How Tooling and Molding Works

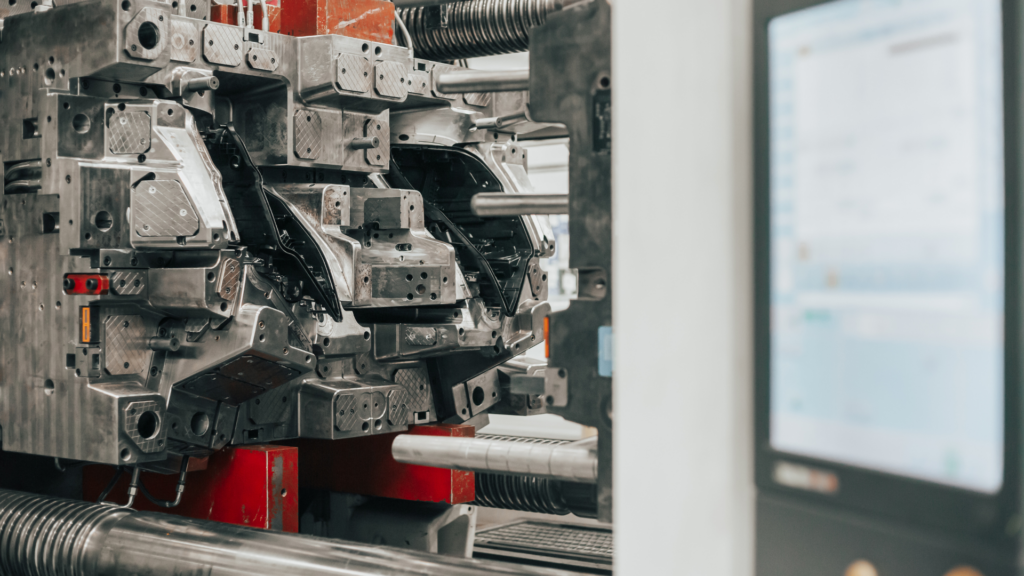

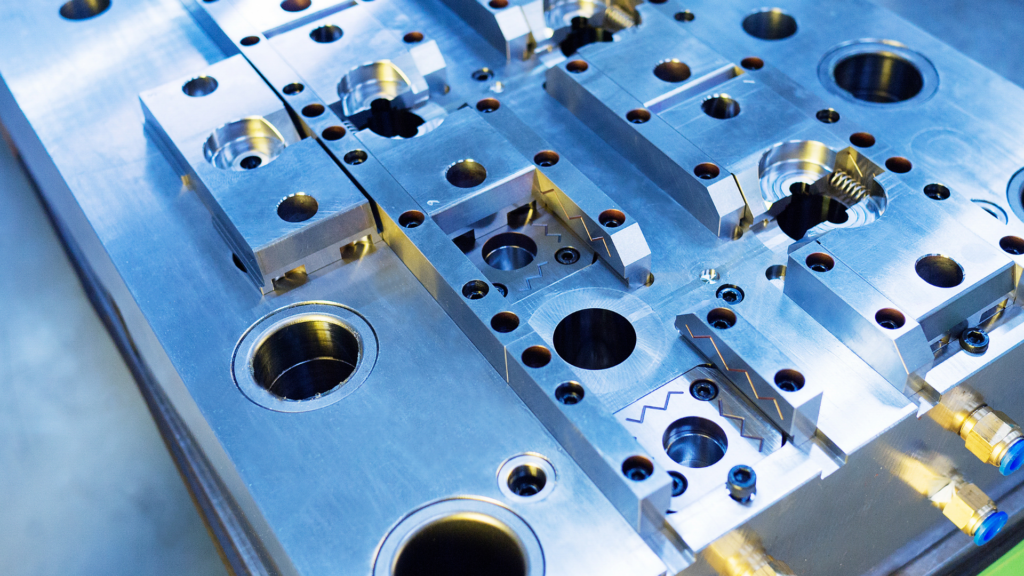

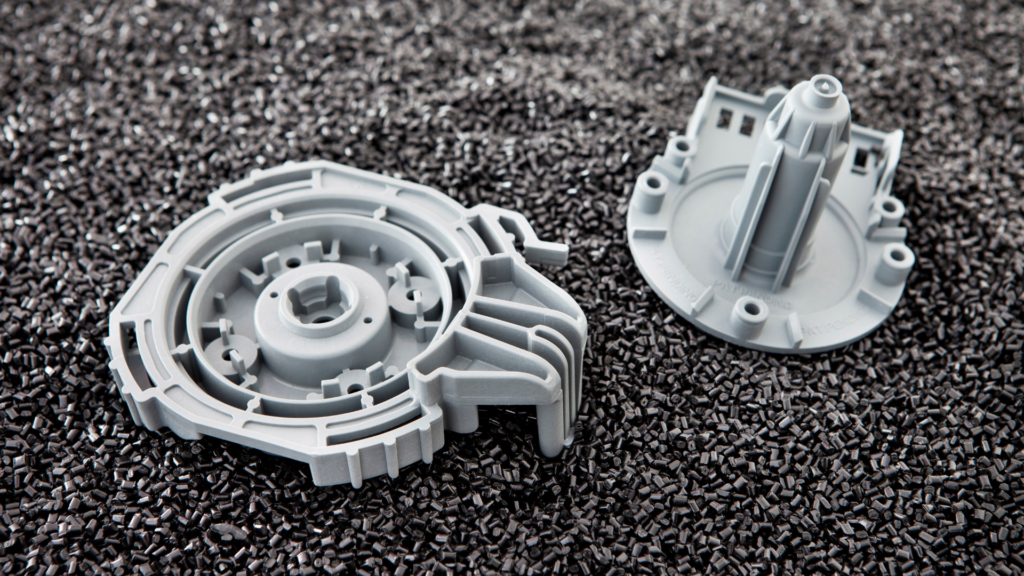

The team at UPTIVE has accelerated this process for faster tooling turnaround with multiple options, including rapid injection tooling, bridge tooling, and production tooling. Plastic injection molding is a process that utilizes heated barrel injection to fill an engineered mold with plastic. The liquid plastic is forced into the cavity of the accurately designed mold, cooled until solidified, and then removed, creating a three-dimensional product. By manipulating heat and pressure, this method can reliably mold a variety of products with speed and accuracy.

Here’s how our injection tooling and molding solutions can help you:

- Ensure precision with customized tooling matched to the best resin that meets your design criteria.

- Decrease cycle times for tool inserts with mold bases uniquely designed for fast and low-volume molds.

- Meet quality expectations with inspection criteria per your industry standards, including first article inspection reports and PAPP’s.

- Give you more design choices, such as complex geometries, undercuts, threads, etc.

Our Plastic Injection Molding and Tooling Capabilities

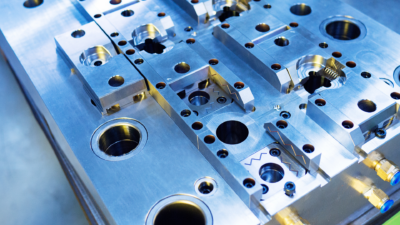

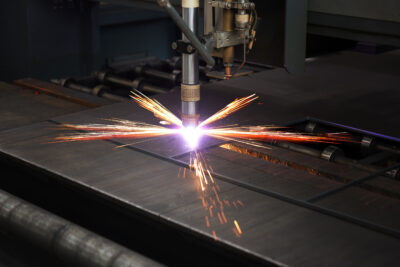

For faster creation of steel and aluminum molds for your parts, UPTIVE utilizes state-of-the-art equipment including high-speed 5-axis CNC machines, EDM, and surface and form grinders. We also give you the ability to create custom mold bases for intricate or high-volume projects. Our systems are made to generate quick-turn parts that meet your standards of exactness, robustness, and lightness while featuring complex part geometries suitable for injection molding.

Injection Molding

Injection Tooling

Urethane Casting

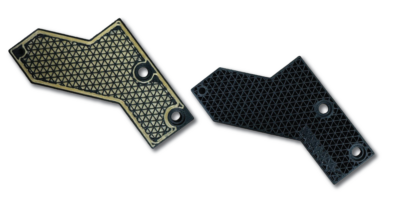

Rapid Injection Tooling Materials

| Material | Description | Ideal for | Finishes | Spec Sheet |

|---|---|---|---|---|

| Aluminum Tooling | Excellent thermal conductivity and low cost | Low to high-volume production runs, prototype development, and quick-turn projects | Smooth or textured surface finish, and can be post-processed with various coatings or anodizing for improved appearance and durability | Spec Sheet |

| DME Steel Tooling | Versatile and commonly used steel material with high wear resistance, good machinability, and availability in various sizes | Medium to high-volume production runs | Smooth or textured surface finish, and can be post-processed with various coatings, plating, or painting for corrosion resistance and improved aesthetics | Spec Sheet |

| H-13 and S-7 Steel Tooling | High-performance steel materials that are known for their excellent thermal conductivity, toughness, and resistance to wear and heat | High-volume production runs and demanding applications, such as automotive and aerospace components | Smooth or textured surface finish, and can be post-processed with polishing, texturing, or coatings for improved appearance and functionality | Spec Sheet |

| NAK 80 Steel Tooling | High-performance steel material that is known for its excellent dimensional stability, high polishability, and resistance to wear and corrosion | Complex injection molding applications, such as medical and optical components | High-gloss, mirror-like finish, and can be post-processed with polishing or texturing for improved appearance and functionality | Spec Sheet |

| P-20 Steel Tooling | High-quality, pre-hardened steel material that is known for its good machinability and durability | Medium to high-volume production, such as automotive and consumer goods applications | Smooth or textured surface finish, and can be post-processed with various coatings or polishing for improved appearance and durability | Spec Sheet |

This is a sampling of injection tooling and molding materials we work with. See more information on available materials and specs here.

Injection Molding & Tooling Design Guide

The team at UPTIVE has accelerated this process for faster tooling turnaround with multiple options, including rapid injection tooling, bridge tooling, and production tooling. Download this design guide to learn more.

Why Customers Choose UPTIVE

Latest Insights

What is Sheet Metal Fabrication?

Embracing Earth Day Every Day: The Environmental Benefits of Domestic Manufacturing

Composite Materials in Additive Manufacturing