Educating Our Customers is Critical

At UPTIVE, we’re here to give you the knowledge, insights, and expertise you need to make informed decisions about your part-production needs. That’s why we’re building and constantly adding to this Knowledge Base, to help you understand how to apply advanced manufacturing technologies to your product design.

Design Guides

Our design guides provide an overview of best practices in order to design your parts for manufacturability from the outset.

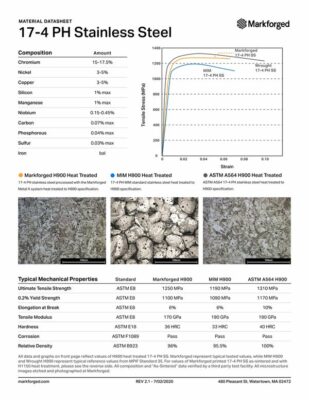

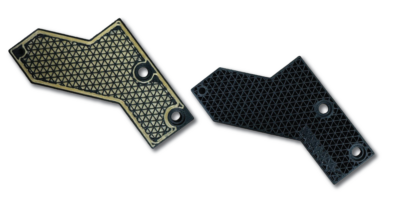

Spec Sheets

Detailed information and data for all materials and technologies used to help you understand everything that goes into a specific part.

Case Studies

Our success is your success. Read some of the major milestones we’ve crossed with our customers and get ideas for how we can help you with your manufacturing needs.

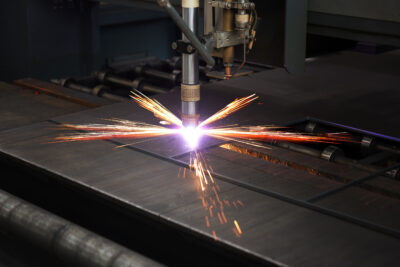

Videos

View content about technologies that are changing how manufacturers work, and that may apply to your parts-production needs. If you have questions on manufacturing, we have the resources to help you answer them!

Webinars

Webinar topics range from deciding between additive manufacturing and traditional to in-depth discussions on rapid injection tooling.

Blog Posts

The latest in news and thought leadership to help you stay up to date on the latest advancements in digital manufacturing.