How Stereolithography Works

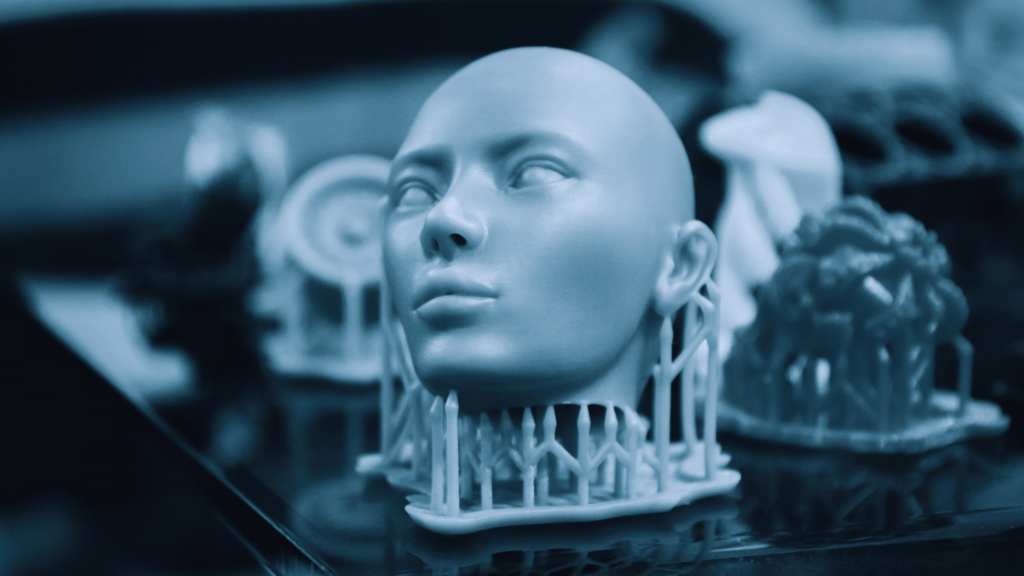

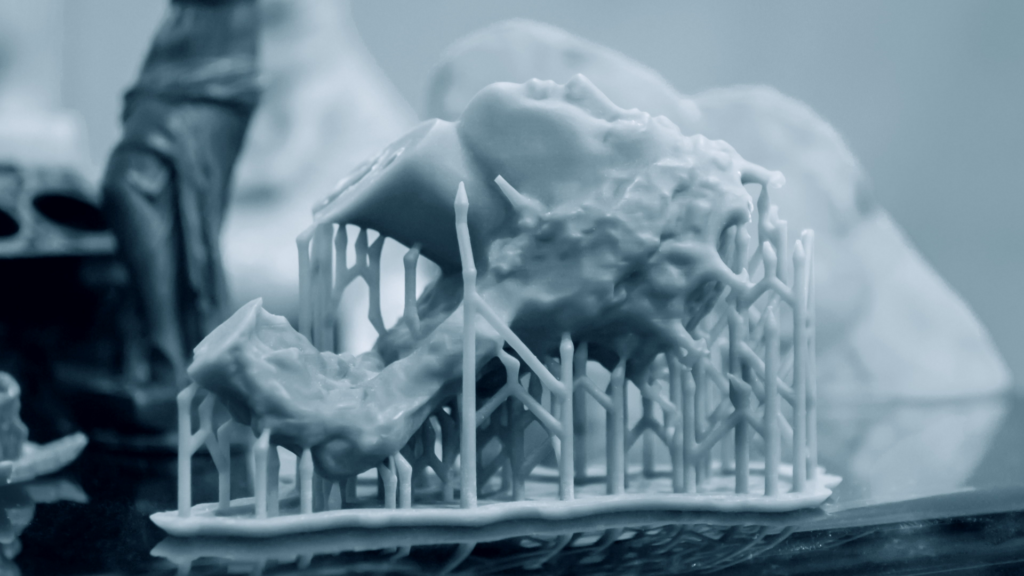

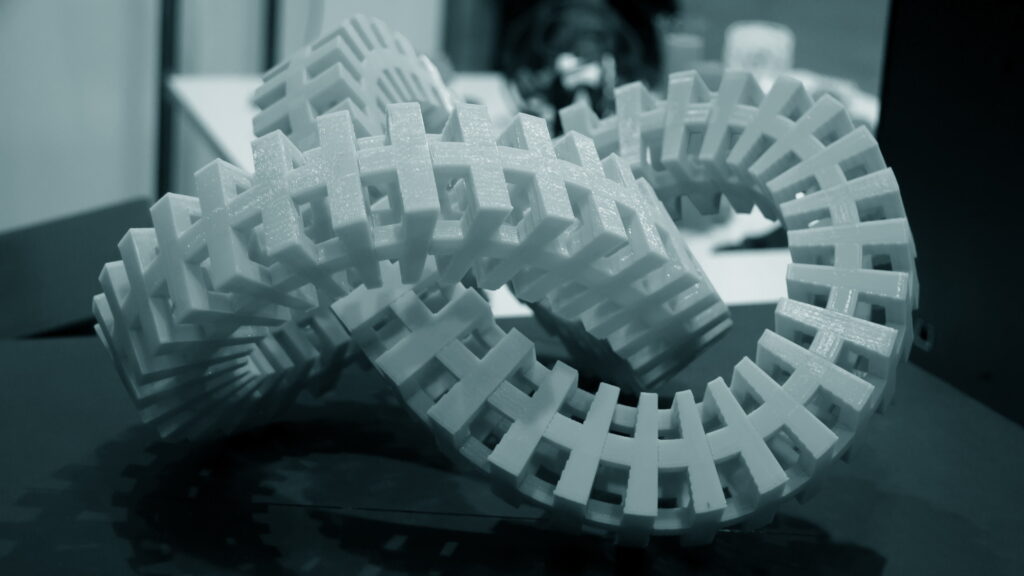

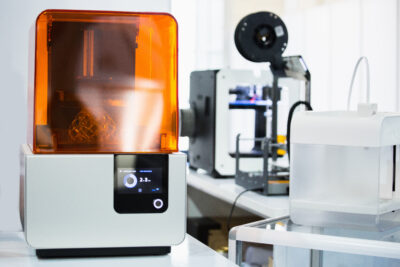

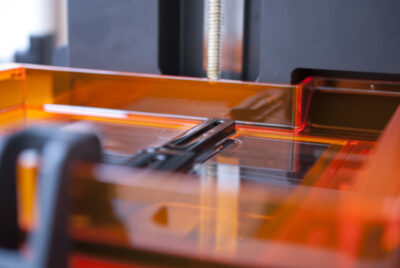

Stereolithography (SLA) is an advanced 3D printing process used to manufacture prototypes and parts quickly and with high accuracy. This method works by using a laser-based system that builds parts, layer by layer, using a photosensitive epoxy-based polymer. Once the model has been printed, it’s cured with UV light to solidify the resin material and strengthen its structure. SLA machining offers an efficient way to produce accurate parts with quality surface finish and adequate mechanical properties.

Here’s how our SLA solutions can help you:

- Produce high precision, quality 3D models with fine details and complex geometries faster and more cost-effectively.

- Accelerate design processes for just about any part: form/fit models, mechanical models, master patterns for cast urethane, etc.

- Create quality surface finishes using a variety of paints and textures for highly-cosmetic show models.

- Eliminate the need for hazardous filaments and powders for more eco-friendly additive manufacturing.

Our Stereolithography Capabilities

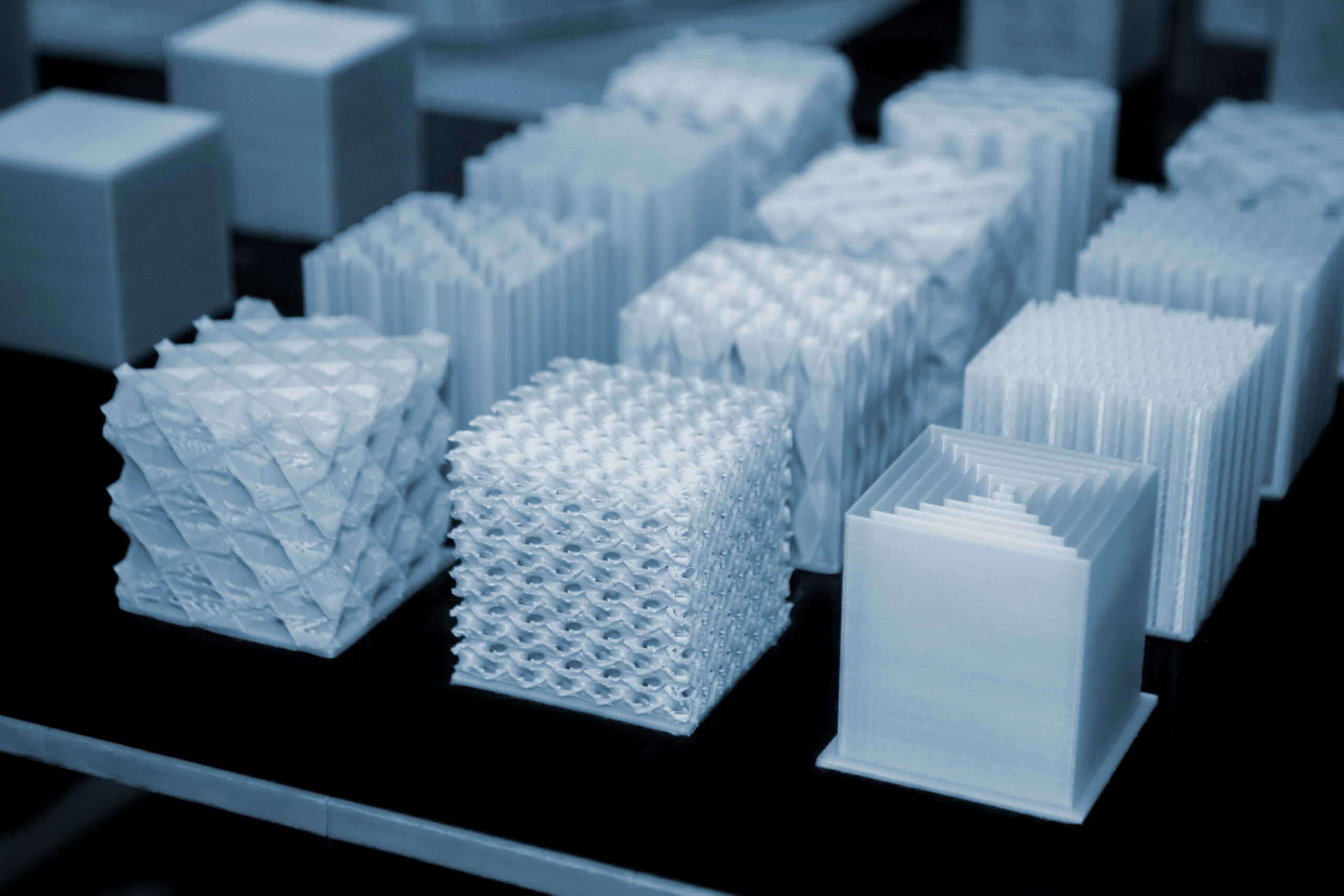

Stereolithography is one of the most popular 3D printing technologies in additive manufacturing because it’s a fast, affordable way to build extremely high-resolution parts for rapid prototyping and end-use, low-volume runs. Our SLA capabilities offer unmatchable speeds with the quality you need for a wide range of detailed prototyping applications.

High Accuracy

Rapid Turnaround

Design Flexibility

Viable Alternative

Functional Testing

SLA Material Comparison

| Material | Description | Ideal for | Finishes | Spec Sheet |

|---|---|---|---|---|

| Accura 25 | Rigid and strong material that has good dimensional accuracy and detail resolution | Medical devices, prototypes, and other applications | Sanding, Polishing, Coating, Painting, Laser Marking, Vapor Smoothing | Spec Sheet |

| Accura 60 Clear | Clear and rigid material that is suitable for creating parts such as lenses and other optical applications | Lenses, optical filters, and other components | Sanding, Polishing, Vapor Smoothing | Spec Sheet |

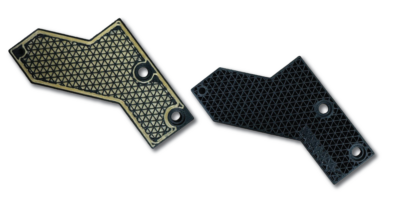

| Accura Xtreme White 200 | High-strength and rigid material that is suitable for creating parts with thin walls and intricate geometries | Molds, tooling fixtures, and other components | Sanding, Polishing, Coating, Painting, Laser Marking, Vapor Smoothing | Spec Sheet |

| Next (white) | Rigid and strong material that is suitable for creating parts with high detail resolution and dimensional accuracy | Prototypes, models, and other components | Sanding, Polishing, Coating, Painting, Laser Marking, Vapor Smoothing | Spec Sheet |

| Somos 11122 | High-strength and durable material that is suitable for creating parts such as snap fits and living hinges | Snap fits, living hinges, and other flexible components | Sanding, Polishing, Coating, Painting, Laser Marking Vapor Smoothing | Spec Sheet |

This is a sampling of SLA process materials we work with. See more information on available materials and specs here.

Why Customers Choose UPTIVE

Latest Insights

What is Sheet Metal Fabrication?

Embracing Earth Day Every Day: The Environmental Benefits of Domestic Manufacturing

Composite Materials in Additive Manufacturing