How HP Multi Jet Fusion Works

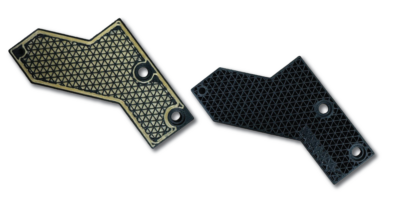

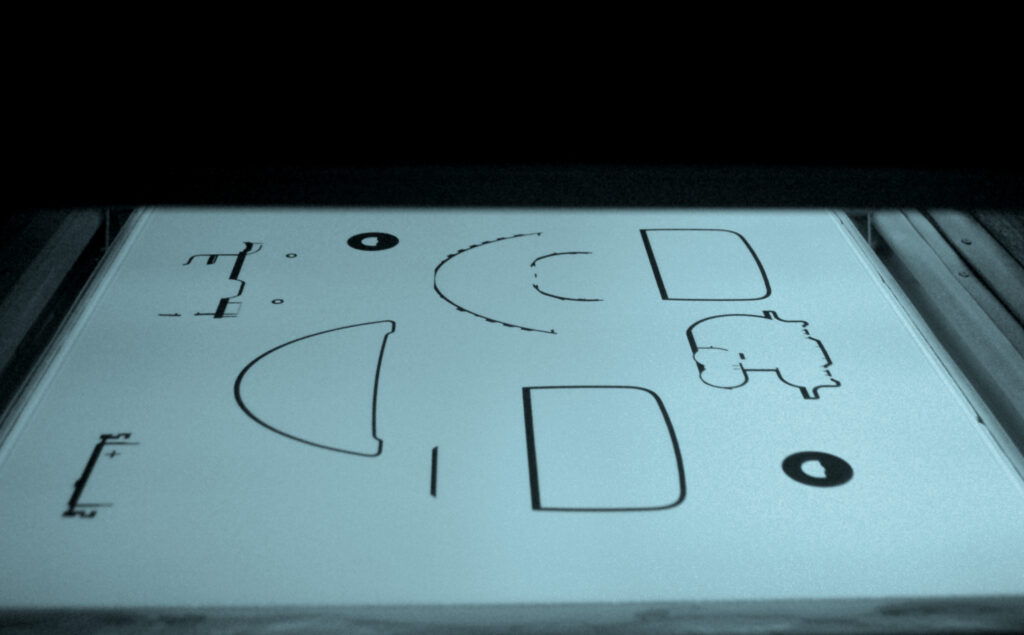

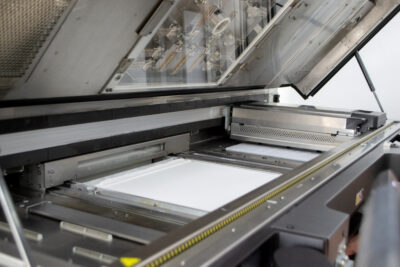

Multi Jet Fusion (MJF) is a revolutionary HP additive technology that heat fuses parts at the voxel (volumetric-pixel) level and uses thermal inkjet arrays to quickly print complex and intricate parts. It’s essentially a powder bed technology that uses your CAD file to print layer by layer, adding fusing and detailing agents and high-intensity light to fuse the material wherever the ink is deposited. MJF parts can be produced with a variety of materials, including polymers and springy, durable elastomers.

Here’s how our MJF solutions can help you:

- Create layers of highly accurate parts with intricate details and aesthetics, in a single piece or sub-components.

- Simplify design and manufacturing processes to reduce processing time and costs while ensuring precision.

- Produce rubber-like parts with advanced materials like the new production-ready elastomeric, Thermoplastic Polyamide (TPA).

- Build parts that perform well in cold and warm environments with multiple color and surface finishing options.

- Get the superior isotropic properties and exceptional mechanical performance you need from HP MJF parts.

Our HP Multi Jet Fusion Capabilities

One of the UPTIVE founding companies, GoProto, is one of the initial six foundation partners globally that meets the very high standards of acceptability in the HP Digital Manufacturing Network (DMN). We consistently meet the high quality and stability standards that HP demands (and verifies) of its partners for solutions engineering, production capacity, consistency, and repeatability of parts. With this solution, we can help guide your engineering teams to achieve increased design innovation and value in the product design process.

Parts On-Demand

Leading Expertise

Multiple Materials

Complex Aesthetics

Finishing Options

MJF Materials Comparison

| Material | Description | Ideal for | Finishes | Spec Sheet |

|---|---|---|---|---|

| PA-11 | Tough and flexible material that has good impact resistance and low friction properties | Gears, bearings, and other components | Dyeing, Painting Coating, Electroplating Vapor Smoothing | Spec Sheet |

| PA-12 | Tough and durable material that has good chemical resistance and low friction properties | Housings, brackets, and other components | Dyeing, Painting Coating, Electroplating Vapor Smoothing | Spec Sheet |

| PA-12 Full Color | Full-color PA-12 material that has similar properties to PA-12 | Prototypes, models, and other components | Vapor Smoothing | Spec Sheet |

| PA-12 GB | Glass-bead-filled PA-12 material that has improved stiffness and dimensional stability | Gears, bearings, and other components | Dyeing, Painting Coating, Electroplating Vapor Smoothing | Spec Sheet |

| Polypropylene | Lightweight and affordable material that has good chemical resistance and low friction properties | Housings, brackets, and other components | Vapor Smoothing | Spec Sheet |

| TPA | Flexible and strong material that has good chemical resistance and toughness | Gaskets, seals and other flexible components | Vapor Smoothing-Dyeing-Painting-Coatings- | Spec Sheet |

| TPU | Flexible and rubber-like material that has good impact resistance and toughness | Gaskets, seals, and other flexible components | Vapor Smoothing-Dyeing-Painting-Coatings- | Spec Sheet |

This is a sampling of HP MJF materials we work with. See more information on available materials and specs here.

Multi Jet Fusion (MJF) Design Guide

Multi Jet Fusion (MJF) is a revolutionary HP additive technology that enables you to quickly print complex and intricate parts. Download this design guide to learn more about HP MJF manufacturing options.

Why Customers Choose UPTIVE

Latest Insights

What is Sheet Metal Fabrication?

Embracing Earth Day Every Day: The Environmental Benefits of Domestic Manufacturing

Composite Materials in Additive Manufacturing