How CNC Machining Works

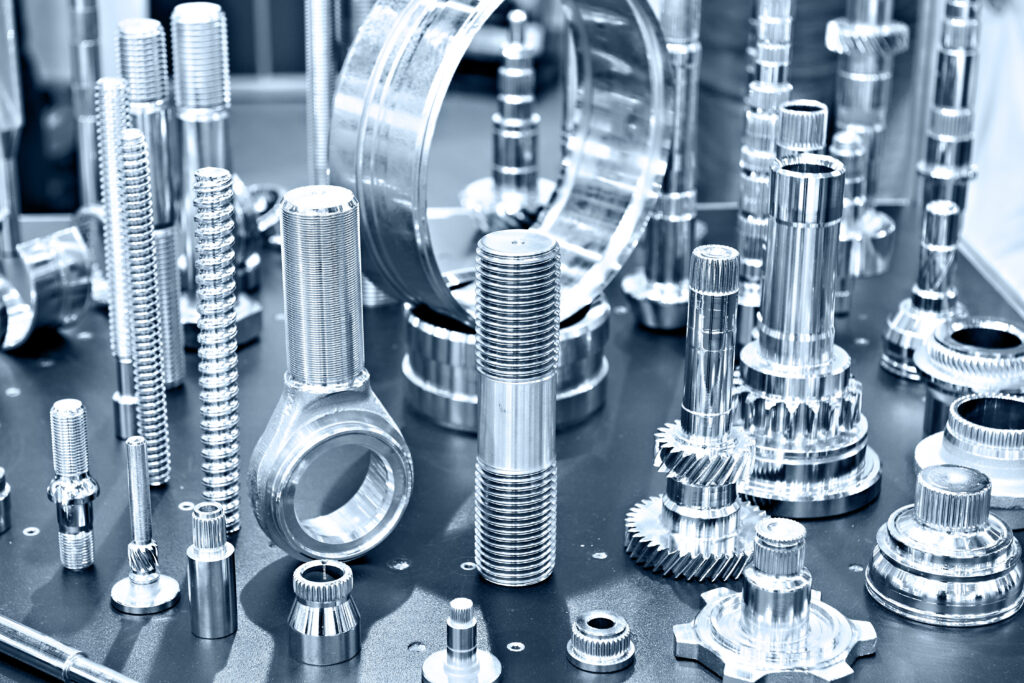

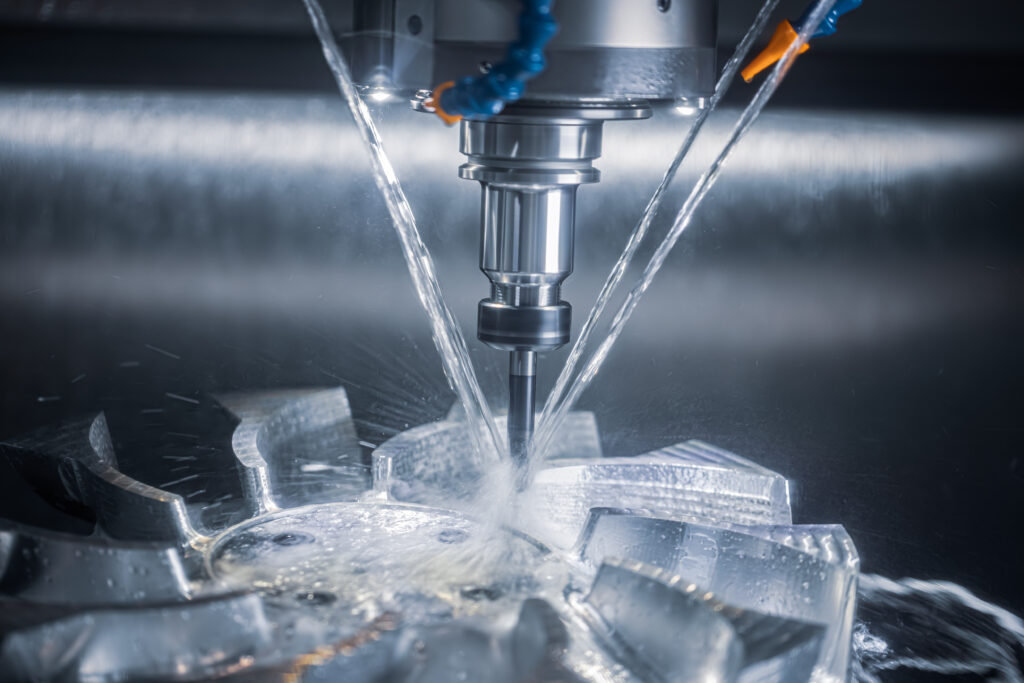

CNC machining is a precise, subtractive process that begins with programming a combination of CNC tools to build a part directly from a CAD file. The machines etch out the design from a solid block of metal or other material to reveal the part shape. For larger or more complex parts,we’ll create the part in sections, then bond the sections back together to form a highly accurate part with a higher quality surface that’s ready for plating, painting or polishing.

Here’s how our CNC machining solutions can help you:

- Accelerate precision and timelines for tooling, progressive dies, and assembly fixtures in higher quantities.

- Produce more complex parts with a variety of materials: aluminum, stainless steel, titanium, Invar, Kovar, brass, plastics, etc.

- Take designs to production faster, including prototypes with complex geometries via CNC prototyping.

- Create metal and non-metal surfaces with better acceptance of coatings and a variety of paint finishes.

Our CNC Machining Capabilities

Our CNC machining solutions offer more speed and material versatility to take your design from prototyping to production. Our team will work with you to ensure support on low, medium and large-volume production with quick turnaround times for prototypes, short runs and pre-production trials. Our materials and systems improve joining characteristics, increase uniformity of hardness/grain structure, and improve surface quality for more available finishing options.

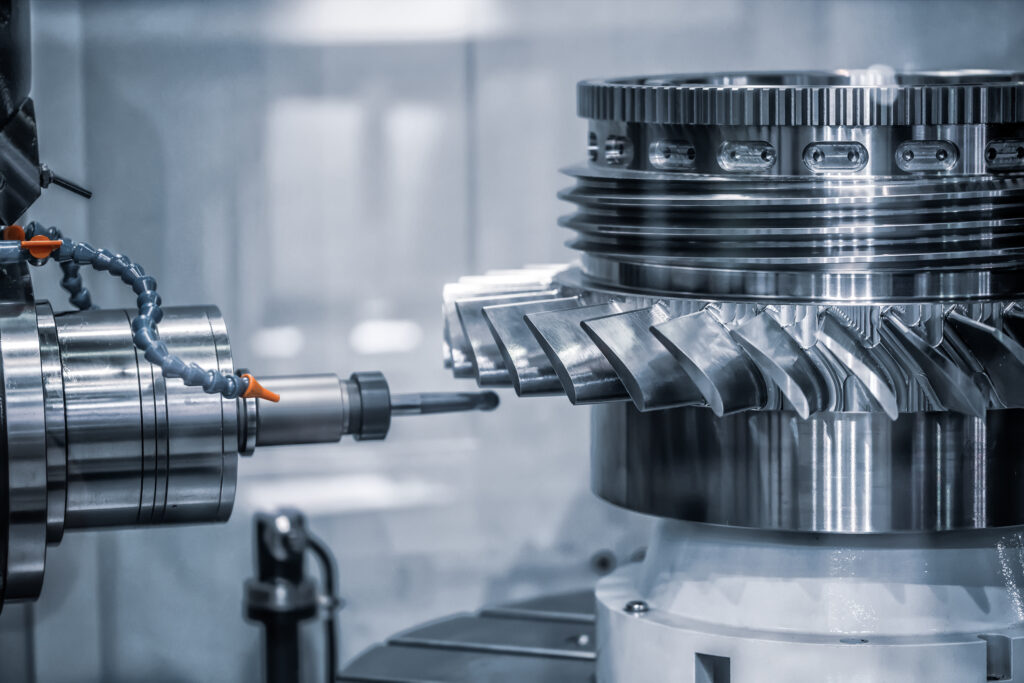

CNC Milling

CNC Turning

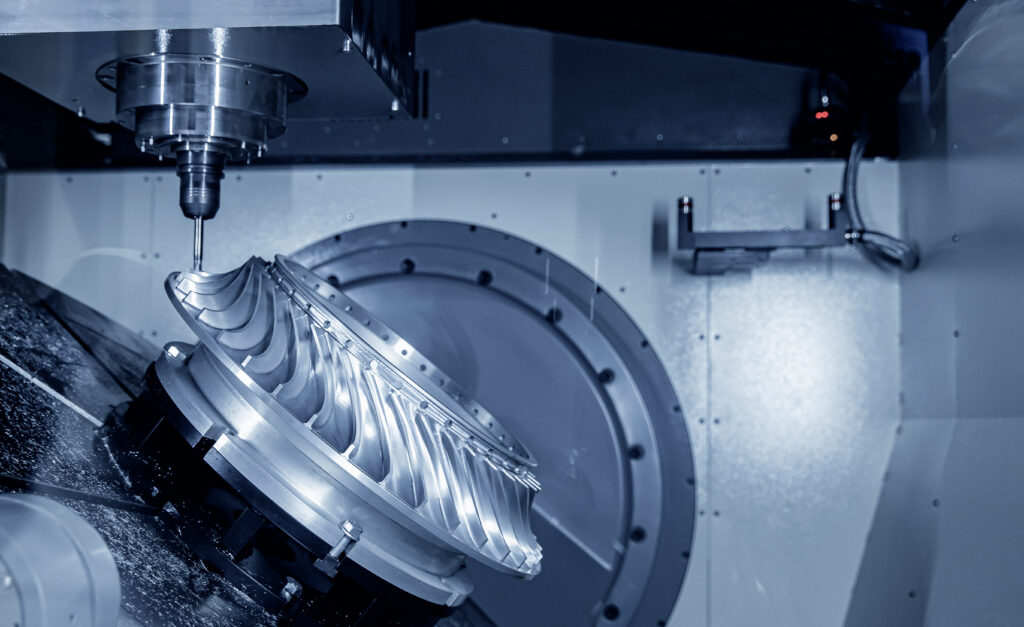

CNC Prototyping

CNC Machining Materials Comparison

| Material | Description | Ideal for | Finishes | Spec Sheet |

|---|---|---|---|---|

| ABS – v0 FLAME-RATED || Black | ABS material that is formulated to meet flame retardant standards for applications where fire safety is a concern | Electrical enclosures and automotive components | Polishing, texturing, or painting, for a smooth and attractive appearance | Spec Sheet |

| ABS || Natural (Off-White) or Black | Versatile and affordable material that is known for its good impact resistance and toughness | Enclosures, housings, and consumer goods | Polishing, texturing, or painting, for a smooth and attractive appearance | Spec Sheet |

| ACRYLIC || Clear | Transparent material that is known for its optical clarity, UV resistance, and scratch resistance | Lighting fixtures, displays, and lenses | Polishing, texturing, or painting, for a smooth and attractive appearance | Spec Sheet |

| Aluminum AL6061-T6 | Lightweight and strong material that is known for its good corrosion resistance and excellent machinability | Aerospace components, automotive parts, and consumer goods | Electroplating, anodizing, or powder coating, for improved corrosion resistance, durability, and appearance. Additionally, these materials can be polished, textured, or sandblasted to achieve desired surface finish | Spec Sheet |

| Copper Alloy | Non-ferrous material that is known for its high electrical and thermal conductivity, making it suitable for electrical and heat transfer applications | Electrical connectors, heat sinks, and plumbing fittings | Electroplating, anodizing, or powder coating, for improved corrosion resistance, durability, and appearance. Additionally, these materials can be polished, textured, or sandblasted to achieve desired surface finish | Spec Sheet |

| NAK 80 | High-performance steel material that is known for its excellent dimensional stability and resistance to wear and corrosion | High-precision molds, injection molding tools, and industrial components | Electroplating, anodizing, or powder coating, for improved corrosion resistance, durability, and appearance. Additionally, these materials can be polished, textured, or sandblasted to achieve desired surface finish | Spec Sheet |

| NYLON || Natural (Off-White) or Black | Versatile material that is known for its high strength, toughness, and durability | Gears, bearings, and structural components in automotive, aerospace, and industrial applications | Polishing, texturing, or painting, for a smooth and attractive appearance | Spec Sheet |

| PC+ABS || Black | Blend of PC and ABS materials that combines the toughness of ABS with the heat resistance of PC | Automotive components, electronic housings, and appliances | Polishing, texturing, or painting, for a smooth and attractive appearance | Spec Sheet |

| POLYCARBONATE || Black or Clear | Tough and transparent material that is known for its excellent impact resistance and heat resistance | Safety goggles, electronic components, and automotive lighting | Polishing, texturing, or painting, for a smooth and attractive appearance | Spec Sheet |

| POLYPROPYLENE || Black | Lightweight and affordable material that is known for its good chemical resistance and low friction | Living hinges, containers, and medical devices | Polishing, texturing, or painting, for a smooth and attractive appearance | Spec Sheet |

| SKD11 Steel | High-carbon and high-chromium steel material that is known for its high hardness, wear resistance, and toughness | Stamping dies, cutting tools, and machine components | Electroplating, anodizing, or powder coating, for improved corrosion resistance, durability, and appearance. Additionally, these materials can be polished, textured, or sandblasted to achieve desired surface finish | Spec Sheet |

| ULTEM || Translucent Amber or Black | High-performance material that is known for its excellent heat resistance, strength, and stiffness | Electrical insulators, aerospace components, and medical equipment | Polishing, texturing, or painting, for a smooth and attractive appearance | Spec Sheet |

This a sampling of CNC machining materials we work with. See more information on available materials and specs here.

3D vs CNC Machining: Which One & When - Webinar

Watch a recording of our recent webinar titled “3D Printing vs CNC: Which One, and When?” where we explore advantages and considerations for these two manufacturing technologies, in order to help you make an informed decision for your business.

Why Customers Choose UPTIVE

Latest Insights

Embracing Earth Day Every Day: The Environmental Benefits of Domestic Manufacturing

5 Common CNC Machining Design Mistakes to Avoid

The Difference Between Jigs and Fixtures