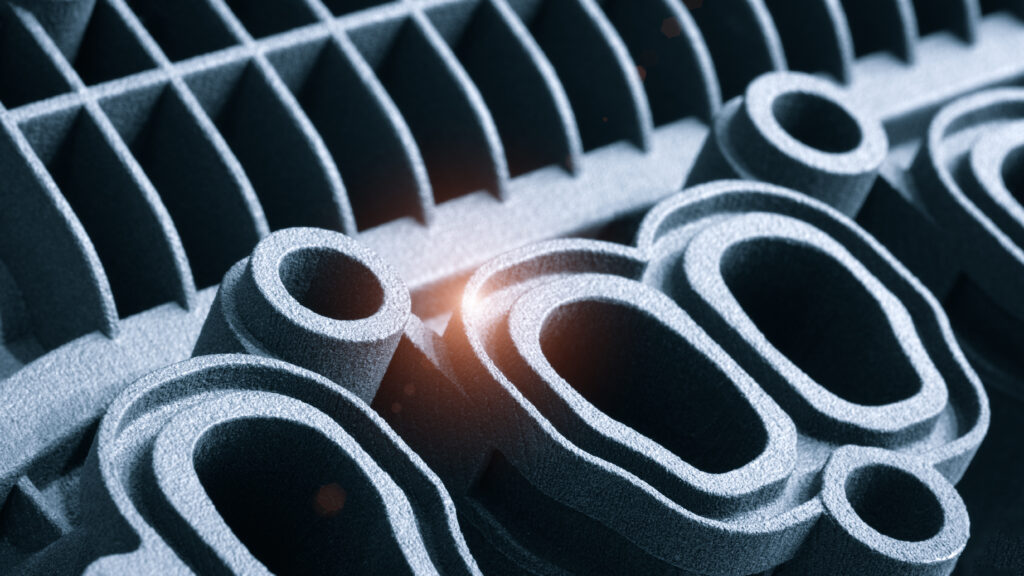

How Selective Laser Sintering Works

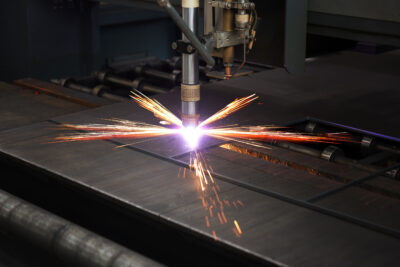

Selective Laser Sintering (SLS) is an advanced additive manufacturing process to create 3D parts out of a wide range of polymers, such as powdered nylons. In the SLS process, high-powered lasers heat and fuse the material together, layer by layer, forming the final 3D product with intricate details and internal channels. Due to its ability to produce complex components without requiring dedicated tooling or support, SLS is quickly becoming an attractive option for product development teams looking for more design freedom.

Here’s how our SLS solutions can help you:

- Produce durable, highly-accurate and detailed parts for end-use, low-volume production, or rapid prototyping needs.

- Deliver parts that can withstand high or low temperatures or exposure to caustic chemicals.

- Control the degree of material melting for complex geometries, flex features, hinges, snaps, clips, and more.

- Provide more material versatility for producing parts in polymers such as nylon, glass-filled nylon, flame-rated nylon and specialty polymer materials.

Our Selective Laser Sintering Capabilities

From automotive to aerospace manufacturing, UPTIVE selective laser sintering delivers more accuracy and strength for your functional end-use parts. It’s just one example of our disruptive additive manufacturing portfolio of powerful and versatile 3D printing options, specially designed for your strong, flexible prototypes and complex geometries.

Rapid Prototyping

Faster Concepting

Affordable to Scale

Quality Surfaces

SLS Materials Comparison

| Material | Description | Ideal for | Finishes | Spec Sheet |

|---|---|---|---|---|

| PA-11 | Tough and flexible material that has good impact resistance and low friction properties | Gears, bearings, and other components | Dyeing, Painting, Coating, Electroplating, Vapor Smoothing | Spec Sheet |

| PA-12 | Tough and durable material that has good chemical resistance and low friction properties | Housings, brackets, and other components | Dyeing, Painting Coating, Electroplating, Vapor Smoothing | Spec Sheet |

| PA-12 Full Color | Full-color PA-12 material that has similar properties to PA-12 | Prototypes, models, and other components | Vapor Smoothing | Spec Sheet |

| PA-12 GB | Glass-bead-filled PA-12 material that has improved stiffness and dimensional stability | Gears, bearings, and other components | Dyeing, Painting Coating, Electroplating, Vapor Smoothing | Spec Sheet |

| Polypropylene | Lightweight and affordable material that has good chemical resistance and low friction properties | Housings, brackets, and other components | Vapor Smoothing | Spec Sheet |

| TPA | Flexible and strong material that has good chemical resistance and toughness | Seals,gaskets and other flexible components | Vapor Smoothing, Dyeing, Painting, Coatings | Spec Sheet |

| TPU | Flexible and rubber-like material that has good impact resistance and toughness | Gaskets, seals, and other flexible components | Vapor Smoothing, Dyeing, Painting, Coatings | Spec Sheet |

This is a sampling of SLS materials we work with. See more information on available materials and specs here.

Why Customers Choose UPTIVE

Latest Insights

Plastic CNC Machining

What is Sheet Metal Fabrication?

Embracing Earth Day Every Day: The Environmental Benefits of Domestic Manufacturing