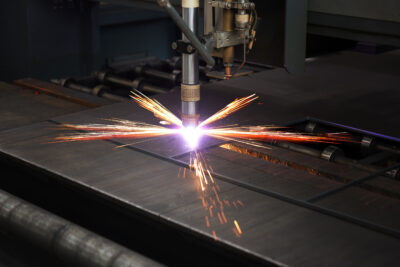

The Latest in Advanced Metals Prototyping & Production for Digital Manufacturing

Our in-house metal material sourcing capabilities enable us to deliver the right combination of cost and performance. We’ll work together to offer a range of metal materials for digital manufacturing that meet your specific needs for both prototyping and production applications, including the latest in Markforged 3D printing technologies.

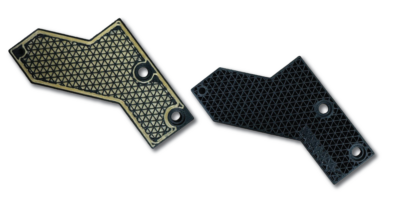

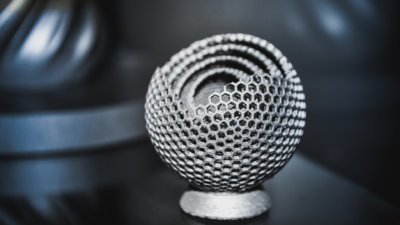

ADDITIVE METAL MATERIALS

| Material | Process | Description | Ideal for | Finishes | Spec Sheet |

|---|---|---|---|---|---|

| A2 Tool Steel | MarkForged, Metal X, Binder Jetting, DED, PBF | Applications that require high resistance to wear and abrasion, excellent toughness, wear resistance, and machinability | Blanking dies, forming dies, and gauges | Machining, heat treatment, polishing surface coating, shot peening | Spec Sheet |

| Aluminum (6061-RAM2) | Direct Energy Deposition, Binder Jetting, Powder Bead Fusion | High strength-to-weight ratio good corrosion resistance weldability good thermal conductivity | Medical devices for its biocompatibility, tooling and fixtures for high temp applications, non-corrosive | Anodizing, powder coating, polishing, painting machining | Spec Sheet |

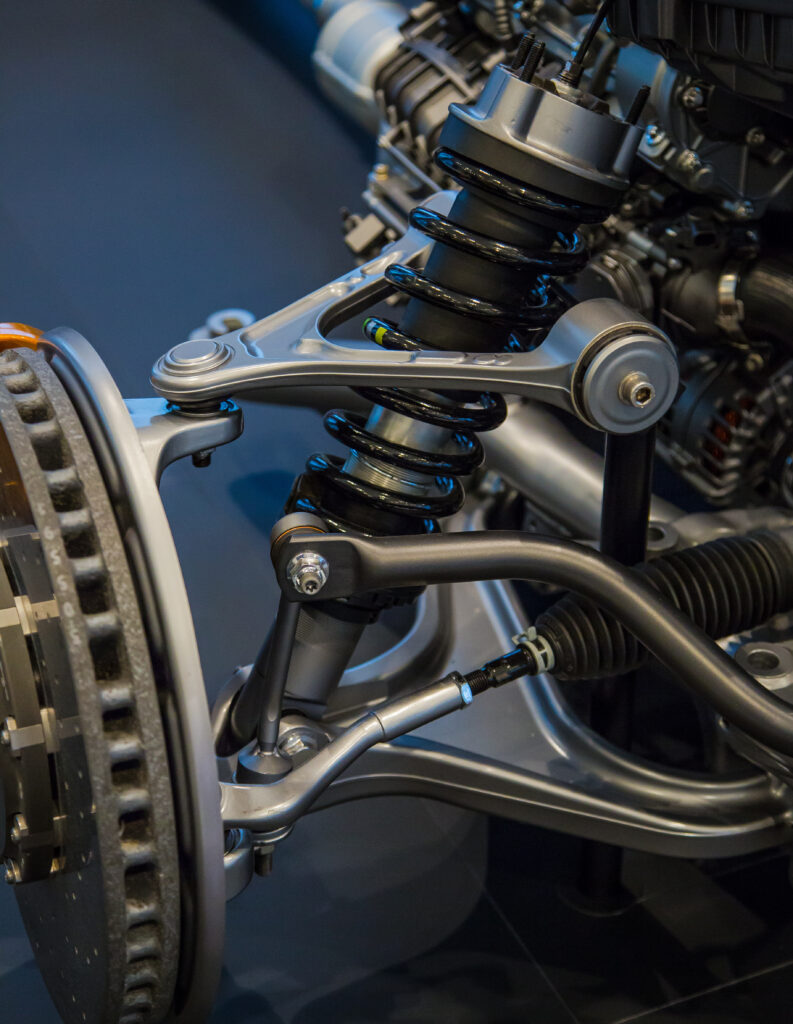

| Aluminum (AlSi10Mg) | DMLS, SLM, Binder Jetting | Additive metal alloy known for its high strength-to-weight ratio for strong, light weight part and corrosion resistance | Aerospace, automotive and industrial manufacturing applications – complex geometries with intricate features | Machining for smooth, precise finishes, anodizing, powder coating | Spec Sheet |

| Aluminum (AlSi12) | Binder Jetting, Direct Energy Deposition | Additive metal alloy known for its high strength-to-weight ratio and thermal and electrical conductivity | Pump and valve components. electrical connectors wheels transmission cases | Anodizing, painting, plating, powder coating, polishing | Spec Sheet |

| Cobalt Chrome | DMLS, EBM | High-strength, wear-resistant alloy It has excellent corrosion resistance, biocompatibility, and can be easily welded or brazed | Aerospace, medical, and dental applications | Sandblasting, polishing, electroplating | Spec Sheet |

| Copper | DED Laser Powder Bed Fusion(PBF), Binder Jetting, Metal X | Highly conductive and ductile metal that has excellent thermal and electrical properties | Electrical and electronic applications, heat exchangers and plumbing components | Chemical etching, electroplating, polishing | Spec Sheet |

| Inconel 625 | DMLS, EBM, Metal X | Family of nickel-based alloys that are highly resistant to corrosion, high temperatures, and mechanical stress | Aerospace, chemical processing, and nuclear applications | Electropolishing, abrasive blasting, passivation | Spec Sheet |

Not sure what you’re looking for? Start your quote to talk with an UPTIVE materials expert. You can also view a full list of material spec sheets here.

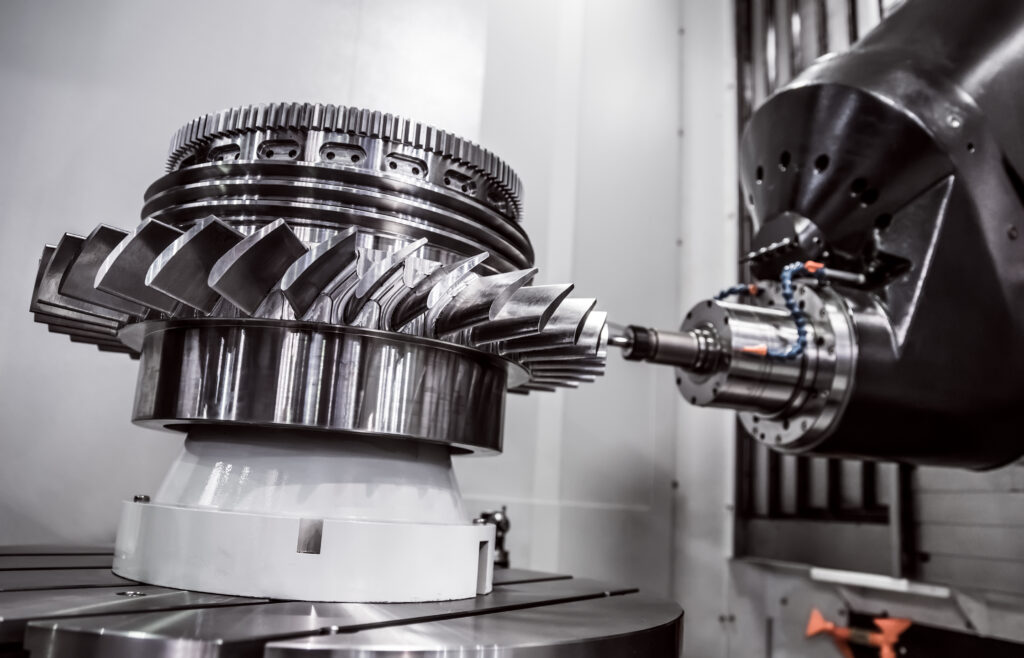

CNC METAL MATERIALS

| Material | Process | Description | Ideal for | Finishes | Spec Sheet |

|---|---|---|---|---|---|

| Aluminum AL6061-T6 | CNC Machining | Lightweight and strong material that is known for its good corrosion resistance and excellent machinability | Aerospace components, automotive parts, and consumer goods | Electroplating, anodizing, or powder coating, for improved corrosion resistance, durability, and appearance Materials can be polished, textured, or sandblasted to achieve desired surface finish | Spec Sheet |

| Aluminum Tooling | CNC Machining | Ideal for low-volume and high-volume production runs, prototype development, and quick-turn projects due to its excellent thermal conductivity and low cost | Low-volume and high-volume production runs, prototype development, and quick-turn projects | Smooth or textured surface finish, and can be post-processed with various coatings or anodizing for improved appearance and durability | Spec Sheet |

| Copper Alloy | CNC Machining | Non-ferrous material that is known for its high electrical and thermal conductivity | Electrical connectors, heat sinks, and plumbing fittings | Electroplating, anodizing, or powder coating, for improved corrosion resistance, durability, and appearance Materials can be polished, textured, or sandblasted to achieve desired surface finish | Spec Sheet |

| DME Steel Tooling | CNC Machining | Versatile and commonly used steel material for injection tooling due to its high wear resistance, good machinability, and availability in various sizes | Medium to high-volume production runs | Smooth or textured surface finish, and can be post-processed with various coatings, plating, or painting for corrosion resistance and improved aesthetics | Spec Sheet |

| H-13 and S-7 Steel Tooling | CNC Machining | High-performance steel materials known for excellent thermal conductivity, toughness, and resistance to wear and heat | High-volume production runs and demanding applications such as automotive and aerospace components | Smooth or textured surface finish, and can be post-processed with polishing, texturing, or coatings for improved appearance and functionality | Spec Sheet |

| NAK 80 Steel Tooling | CNC Machining | High-performance steel material that is known for its excellent dimensional stability, high polishability, and resistance to wear and corrosion | Complex injection molding applications such as medical and optical components | High-gloss, mirror-like finish, and can be post-processed with polishing or texturing for improved appearance and functionality | Spec Sheet |

| NAK 80 | CNC Machining | High-performance steel material known for its excellent dimensional stability and resistance to wear and corrosion | High-precision molds, injection molding tools, and industrial components | Electroplating, anodizing, or powder coating, for improved corrosion resistance, durability, and appearance | Spec Sheet |

| P-20 Steel Tooling | CNC Machining | High-quality, pre-hardened steel material that is known for its good machinability and durability | Medium to high-volume production runs such as automotive and consumer goods applications | Smooth or textured surface finish, and can be post-processed with various coatings or polishing for improved appearance and durability | Spec Sheet |

| SKD11 Steel | CNC Machining | High-carbon and high-chromium steel material that is known for its high hardness, wear resistance, and toughness | Stamping dies, cutting tools, and machine components | Electroplating, anodizing, or powder coating, for improved corrosion resistance, durability, and appearance Materials can be polished, textured, or sandblasted to achieve desired surface finish | Spec Sheet |

Not sure what you’re looking for? Start your quote to talk with an UPTIVE materials expert. You can also view a full list of material spec sheets here.

Latest Insights

What is Sheet Metal Fabrication?

Embracing Earth Day Every Day: The Environmental Benefits of Domestic Manufacturing

Composite Materials in Additive Manufacturing