Our Medical Manufacturing Capabilities

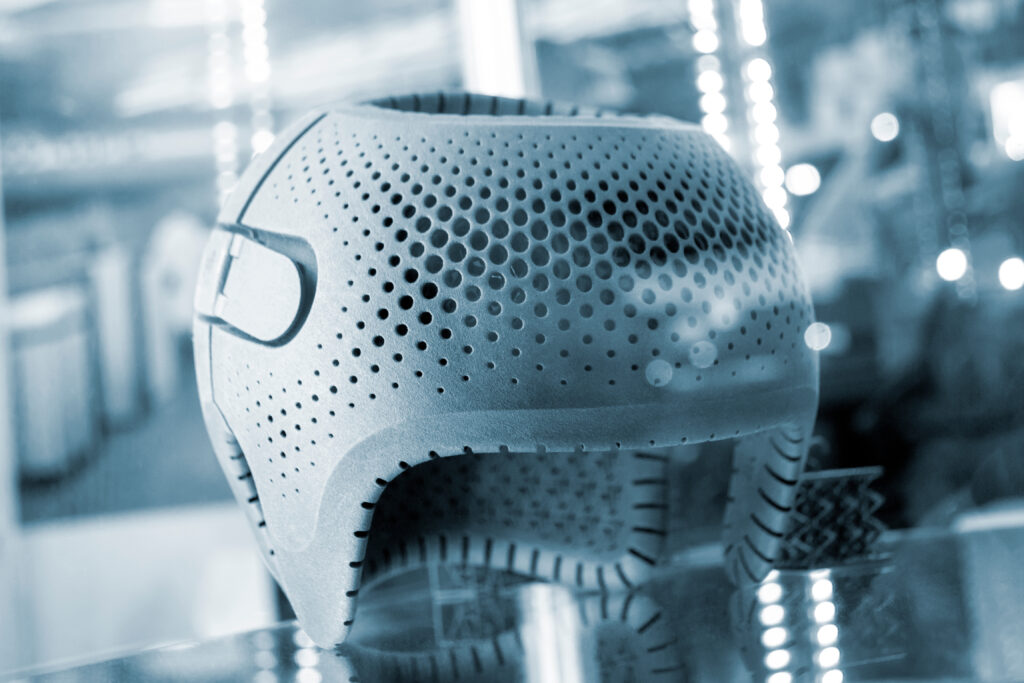

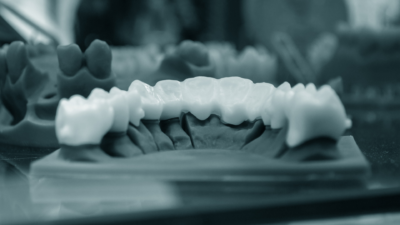

No matter the application, every project requires a specific solution, and we’re focused on helping you select the ideal material and manufacturing technology to take your idea from concept to completion. Whether it’s diagnostic equipment, prosthetics, dental implants, or surgical instruments, medical manufacturers trust UPTIVE’s capabilities to meet their requirements.

Emergent Healthcare - Case Study

UPTIVE and Emergent Healthcare Tackle Knee Replacement Recovery

Seattle Children's - Case Study

On-Demand, Custom Manufacturing To Protect Bus Drivers At Seattle Children’s.