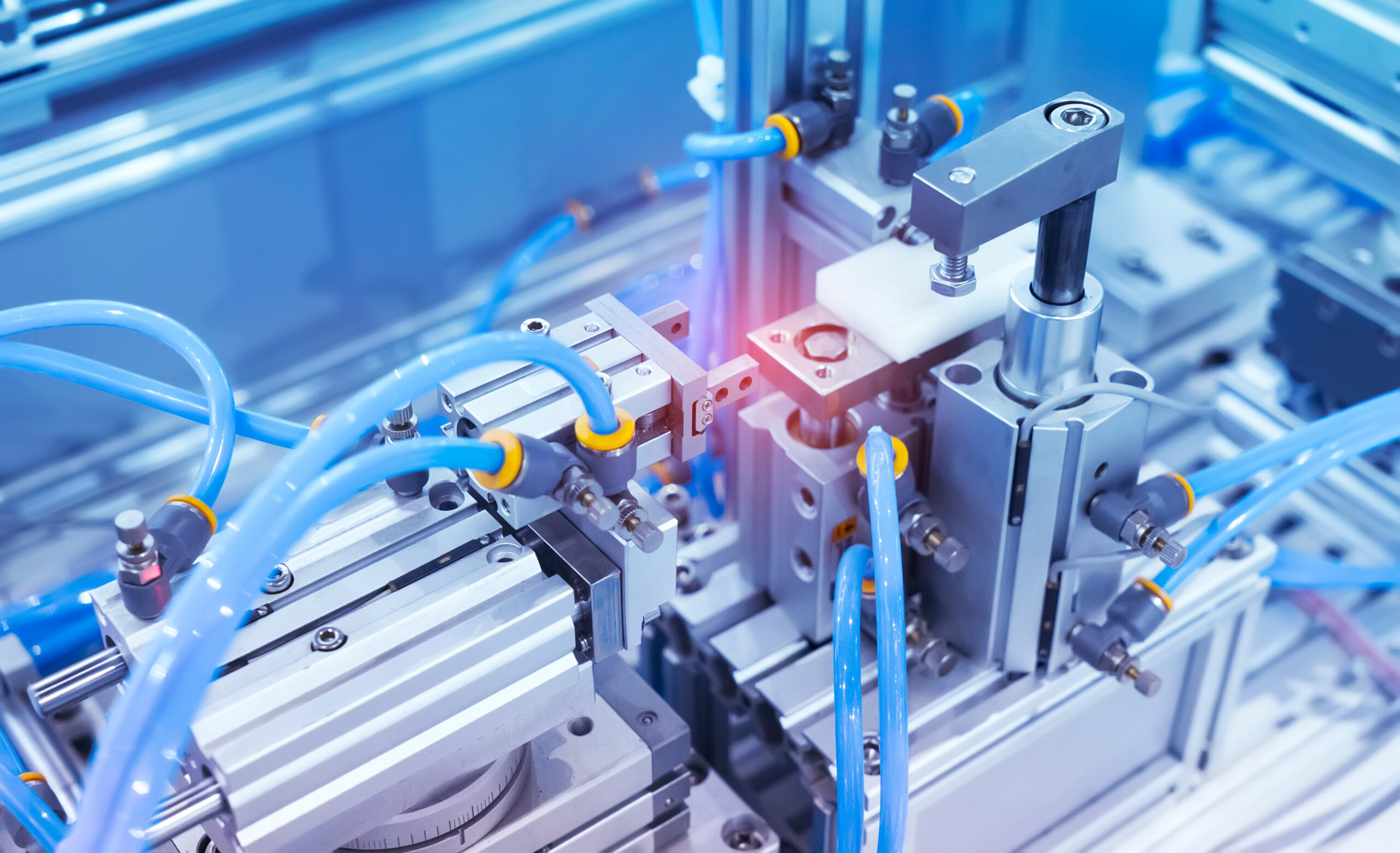

Our Industrial Equipment & Automation Capabilities

We’re here to extend the life of and customize your legacy industrial equipment while advancing your robotic machinery into the digital era. Our plastic and metal manufacturing solutions are designed to revolutionize the way you bring products to market. Our team of experts is ready to match our capabilities and materials to your industry-specific applications.