How Post Processing & Finishing Works

There are a variety of post-processing and finishing options to produce targets ranging from unfinished to photo-realistic results. Just a few techniques include bead-blasting, polishing, dyeing, chemical/vapor/mechanical smoothing, wet paint, Cerakote, hydrographics, metalization, texturing and hardware installation. UPTIVE matches each finishing process that best suits your needs for each part manufacturing application, from 3D printing to CNC machining to injection molding.

Here’s how our processing and finishing solutions can help you:

- Improve part quality to meet compliance requirements for industries such as medical, aerospace, or electronics.

- Enhance a part’s surface characteristics, geometric accuracy, aesthetics, mechanical properties, and more.

- Increase part strength and optimize its resistance for industrial-level performance requirements.

- Ensure uniform smoothness for good aesthetics, with a consistent professional look and feel.

Post Processing & Finishing Capabilities

Below is a sampling of our finishing techniques, which can be modified to suit specific needs and materials. UPTIVE finishing experts have spent years guiding our customers to the right finishing process to help speed time to market and increase profitability.

Vapor Smoothing

Dying

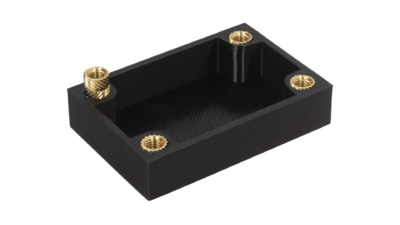

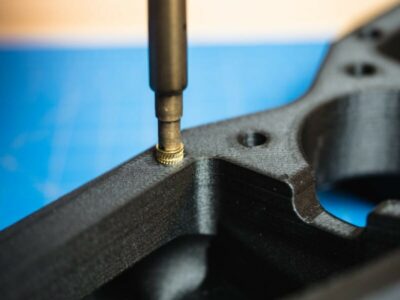

Heat-Set Inserts

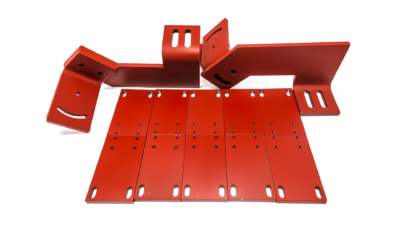

Light Assembly

Finishing Options

Finishing Processes Comparison

| Processes | Description | Ideal For |

|---|---|---|

| Vapor Smoothing | Physical-chemical-based process that can smooth a wide variety of thermoplastic polymers that are printed in MJF, SLS or FDM 3D printing technologies | Consumer products, prototypes, aesthetic models, functional prototypes, and engineering applications requiring improved strength and airtightness |

| Cerakote | Protective ceramic-based thin film coating providing UV resistance, Heat resistance and chemical resistance to MJF parts | Firearms, knives, automotive parts, sporting goods, and other high-performance applications that require durable, corrosion-resistant, and aesthetically pleasing finishes |

| Hydrographics | Method used to apply printed designs onto parts printed with Multi Jet Fusion | Automotive parts, firearms, sporting goods, electronic devices, and various consumer products that can benefit from customized and visually appealing patterns or designs on their surfaces using water transfer printing (hydrographics) |

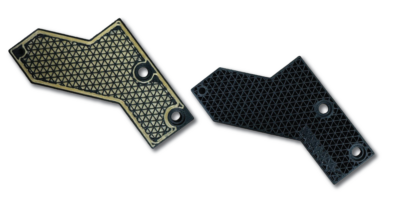

| Metalization | Cosmetic and functional metal plating for parts printed with Multi Jet Fusion | Automotive trim, electronics, decorative objects, consumer products, and various industrial components that can benefit from a metallic appearance and improved conductivity achieved through the process of metalization |

| Dyeing | Application of a selected dye or coloring agent to the surface of the part, allowing it to absorb and achieve the desired color, followed by rinsing and drying to complete the process | Textiles, garments, plastics, 3D printed parts, and various consumer products that can benefit from vibrant colors, customized designs, and enhanced aesthetic appeal achieved through the process of dyeing |

| Painting | Application of a selected paint to the surface of the printed object, enhancing its appearance, adding color, and providing additional protection or finishing, typically through methods such as spray painting or hand brushing | Automotive parts, furniture, artwork, industrial equipment, and various consumer products that can benefit from customized colors, improved aesthetics, and added protection achieved through the process of painting |

This is a sampling of the finishing processes we work with. See more information on available materials and specs here.

Why Customers Choose UPTIVE

Latest Insights

Composite Materials in Additive Manufacturing

5 Ways to Optimize 3D Printed Parts for Post-Processing